Our new designs

-

William Morris - Tulip and Willow

Regular price 12.95 EURRegular priceUnit price / per -

Katsushika Hokusai - Great Wave Blue License

Regular price 12.95 EURRegular priceUnit price / per -

Antonio Canova - The Three Graces

Regular price 12.95 EURRegular priceUnit price / per -

Katsushika Hokusai - Great Wave Beige License

Regular price 12.95 EURRegular priceUnit price / per -

Dante Gabriel Rossetti - The Day Dream

Regular price 12.95 EURRegular priceUnit price / per -

Alphonse Mucha - Cours de Composition d’Art Décoratif

Regular price 12.95 EURRegular priceUnit price / per

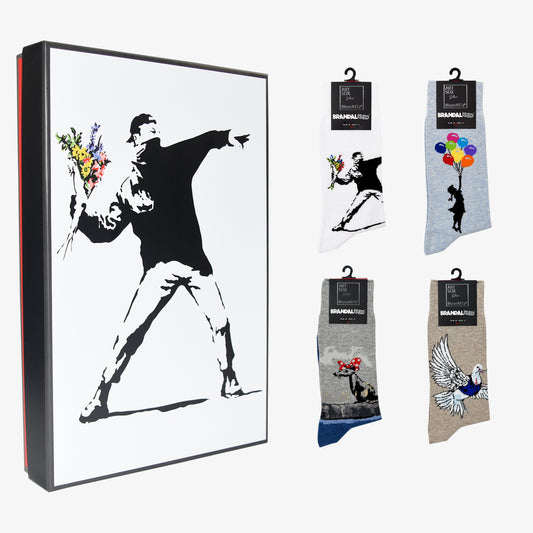

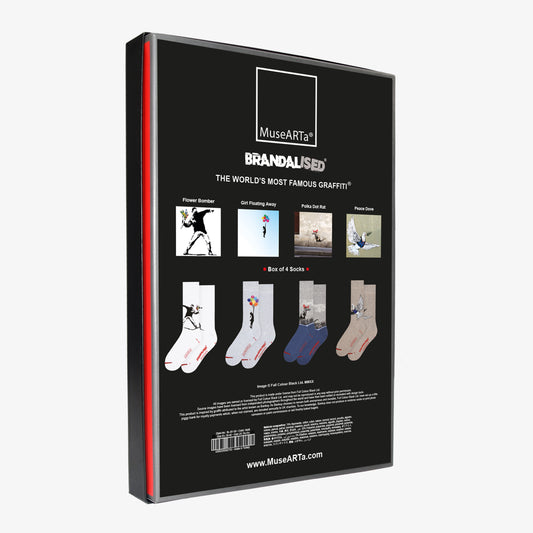

Our "The world's most famous Graffiti" collection

-

The world's most famous Graffiti - Flower Bomber - gift set

Regular price 49.95 EURRegular priceUnit price / per -

The world's most famous Graffiti - Flower Bomber - gift box

Regular price 12.95 EURRegular priceUnit price / per

FAQs

Payment Methods

We offer the following payment methods.

(For the payment method “Sofortüberweisung” we will receive the payment approval after a few working days. After we have received the approval, the order will be shipped immediately.)

Shipping service provider & delivery time

We ship worldwide with DHL.

Shipping within Germany usually takes 1-3 working days.

Shipping to European destination countries usually takes 3-5 working days.

You can find all further information here .

How can I track my order?

As soon as your order has been shipped, you will receive a notification from us with a tracking link.

Can I return or exchange ordered products?

If, for whatever reason, you want to return your order to us, the return is free during the 14-day return period and within Germany. Unfortunately, we cannot cover the shipping costs for returns from abroad. Please click here to create your returns slip and then print it out. It is important that you do not send your package freight collect. As soon as we have received your return, you will of course receive your money back via the chosen payment method.

How does the return of my MuseARTa products work?

If you click here , you will automatically be redirected to DHL. Please fill out the form that opens there completely. You will then receive your return label with which you can send your MuseARTa products back to us within 14 days of receipt.

Please note that creation is only possible for customers with a delivery address in Germany. Unfortunately, we cannot bear the costs for returns from abroad.

If you would like to send a return to us from abroad, please send it to the following address:

MuseARTa GmbH

At Ziggurat 4

53894 Mechernich

Germany

As soon as the goods have been booked in our warehouse, you will receive your credit via the payment method you used when purchasing.

Care instructions for your MuseARTa items

So that you can enjoy your MuseARTa products for as long as possible, we recommend washing them at a maximum of 40 degrees. However, you should not bleach or iron them. Professional cleaning is possible with perchlorethylene.

You can find all further information here .

You want to sell MuseARTa in your shop or are a buyer for a museum shop. Who can you contact about us?

You are welcome to contact us using our B2B contact form . We look forward to hearing from you.

What criteria do we use to select works of art at MuseARTa?

We try to select works of art from all important art eras. Of course, we have to consider whether we can even acquire the rights for the corresponding works of art.

In addition, a work of art must also be feasible. We work with very high-quality machines that can knit up to 17 colors in a row, but if the number of colors goes beyond that, then we sometimes have to say that a work of art cannot be produced as a knitted version.

Why do I find mostly male artists on MuseARTa.com?

We try to create a balanced gender ratio between artists. Unfortunately, this is not so easy, because in the past there were significantly more male artists whose art hangs in museums than there are today, and unfortunately we encounter a negative attitude towards our MuseARTa project more often among contemporary female artists than among male artists. You are welcome to support us here by writing to the relevant museums or artists that we would like to represent. Unfortunately the list is long.

What is the difference between printed and knitted socks?

Our socks are knitted and not printed. That is a crucial difference.

When printing, you can print the sock lying flat, i.e. front and back, but then you have the problem that you have a stripe on the sides where no ink has reached. These two stripes can then be seen as vertical white stripes when the sock is put on.

Alternatively, you can put a sock on one leg and print it all over. This is significantly more expensive and then the white stripes are eliminated. However, with both versions you have the problem that the color intensity is massively lost during printing and you can see the underlying material. In addition, the subject is heavily distorted with this technique.

You could stretch the sock slightly and then print it, but that would have the disadvantage that the motif wouldn't look as nice in the store because you anticipated a certain amount of distortion, but the sock would look very strange on the shelf when unstretched.

How are our socks made?

We knit the socks on single-cylinder machines, usually with an extremely high needle count of 200 needles. This is the number of needles attached to the knitting cylinder.

The different colored threads run into this knitting cylinder. When a place comes where the machine wants to knit a white eye, the machine gets the thread in the color white, knits one or two machines, lets go of the thread and gets the next thread. Another special thing about our machines is that we can process up to 17 colors in a horizontal row.

From the inside, such a sock theoretically looks like a sweater knitted using the jacquard technique. However, the sock would then not be stretchy. A sweater doesn't have to be stretchy because it fits loosely, but with a sock you want it to fit and fit snugly. The problem with the sock is that the front of the foot is wider than the lower leg area directly above the heel. That's where the leg is thinnest and that's where the sock has to sit. But the foot has to fit into the sock, so the sock has to be stretchy.

However, the sock can only be stretchy if the material the sock is made of is stretchy. That's why the substructure of these socks is always made of polyamide with a portion of elastane. Without this share you cannot make these socks.

Now, however, we at MuseARTa would like to make socks with a very high cotton content and cotton is not stretchy. Anyone who has jeans without elastane knows this. Therefore, these non-elastic cotton threads on the inside of the sock have to be cut off during knitting so that they can move within the knitted fabric - that's what the material is called. The thread is cut off and the sock can be stretched. So that the thread does not slip out of the connection of the individual stitches when stretched, it must be cut so that it remains in the sock even when stretched and does not slip out on the outside. But that only works if it has a certain length.

These threads that run on the inside and are not visible as long as the machine does not knit them and then only become visible again when the machine needs exactly this thread in the special color are called float threads. Now if a machine knits one color for a few stitches and then knits another color over a very small number of stitches and then takes the first color to knit again, then the length that the thread flows on the inside may not be there is long enough for the machine to place an automatic knife on the inside of the cylinder and cut the thread. Depending on the machine type, the machine requires between 10 and 12 stitches to be able to cut at all. If there are fewer stitches, the thread stays on the inside and continues to flow.

If a motif has extremely frequent color changes and the float threads are always very short, the machine cannot even start to cut, in such a case the sock would not be stretchable and you cannot put your foot in it.

We try to help ourselves with very complex motifs by turning the socks inside out and cutting threads by hand that cannot be cut automatically with the machine. This works with a float length of around eight stitches, but not with too few stitches, because then the thread would fly out at the front and that wouldn't look nice.

In short: it is a highly complex topic, we use strain measuring machines to check how elastic a sock is and where and we really put a lot of effort into making our socks.

By the way: with double cylinder machines you can let the threads run inside and not cut them, but with this type of machine you cannot process as many colors as we do, nor do you have the option of making a sock in a size range of 36 to 40 or 40 to 46 to make. Double cylinder socks can actually only be made in double sizes. Double cylinder machines are absolutely unsuitable for this type of motif socks.

The threads hanging loose on the inside are not proof of inferior quality, as one often incorrectly reads on the Internet, but rather a necessity and contribute to the socks being more comfortable to wear.

Why do you produce at different locations?

We produce at different locations because not a single location would provide us with what we need. For some motifs we need an extremely large number of colors in a row; such machines run slower because the machine has to slow down with every color change and the cylinder can then rotate faster again. The more frequent the color changes and the more colors are used, the lower the production volume of a machine. This can sometimes only be 2-3 pairs per hour that we produce on one machine.

Other machines can use fewer colors and are therefore more effective. Only through a mix of calculations are we able to offer these highly complex socks at this price, because we also pay license fees for the image usage rights.

In addition, it is often a matter of the availability of yarn. Having yarn in many colors costs more money. Having yarn dyed as needed is cheaper given the corresponding production volume, but it makes you less flexible and you have to be able to cope with the larger quantities.

It also depends on the motif where we give which design. Since a stitch is not square, different machines have different numbers of rows to knit for the same leg length. For us this varies between 220 and 260 rows in height of the leg.

If a motif is particularly high and very detailed, it makes sense to go to a manufacturer where the stitches are not quite as high and therefore more knitted rows fit on the shaft length we specify, so we can work with more detail.